Texas Border Business

By Roberto Hugo González

The McAllen Citizen’s League (MCL), a community-focused group spearheaded by Elva Cerda, recently hosted Keith Patridge, President and CEO of the McAllen Economic Development Corporation (MEDC). Having committed 35 years of his career to economic development and foreign trade in McAllen, Patridge possesses a depth of knowledge and experience that has positioned him at the leading edge of binational economic growth in the region.

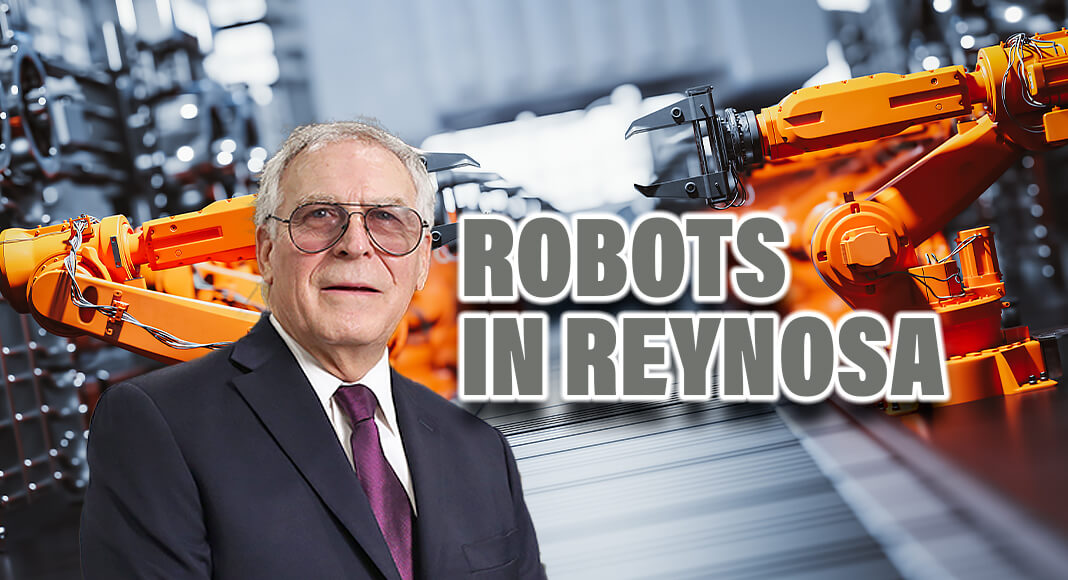

During the McAllen Citizen’s League, Patridge acknowledged the transformative influence of the USMCA (United States-Mexico-Canada Agreement) on local manufacturing practices. Yet, in light of the Covid-19 pandemic, one development has surged to the forefront – the rise of automation, robotics, and artificial intelligence (AI) in manufacturing.

These technological advancements have radically altered production lines. “AI is here, folks,” Patridge stated, noting that the pandemic has accelerated the implementation of automation, robotics, and AI across numerous factories.

In the past, human-operated assembly lines dominated manufacturing plants, where workers worked in tandem to complete the assembly process. However, during the Covid-19’s stringent social distancing protocols forced companies to revise their operational models.

As a solution to maintain production levels, companies turned to robotic technology, integrating robots and cobots (sensor-fitted collaborative robots) into their assembly lines. “We have one company that transformed its operations by integrating 600 robots within a mere span of 60 days,” said Patridge.

Patridge emphasizes that while not all companies have embraced robotics yet, a notable number have adopted them as integral components of their manufacturing processes. Robots present numerous advantages: they do not need food or rest, they remain unaffected by illness, and their consistent operation enhances productivity. Nevertheless, Patridge underscores that this transformation has wider ramifications.

Initially, Mexico’s low labor costs attracted many companies. But, with the rise of robotic labor replacing human workers, labor costs have become less significant. Additionally, higher utility costs in Mexico, intermittent electricity supply issues, and escalating security concerns are prompting companies to reevaluate their manufacturing bases.

Despite these potential obstacles, including government policies, financial risks, security threats, political disputes, and global complications, McAllen and Reynosa continue to blossom into burgeoning industrial hubs. Patridge’s optimistic outlook invites those with investment capital to support the construction of new industrial buildings, as the current demand far surpasses the supply.

Over the years, Patridge’s work has spanned diverse sectors and territories, serving as a catalyst for companies navigating the global marketplace and fostering their strategic growth. His strong relationship with Mexican officials and business leaders in Reynosa and the broader state of Tamaulipas has contributed greatly to the attraction of new investments and jobs, the enhancement of infrastructure, and the promotion of workforce development through education and training programs.